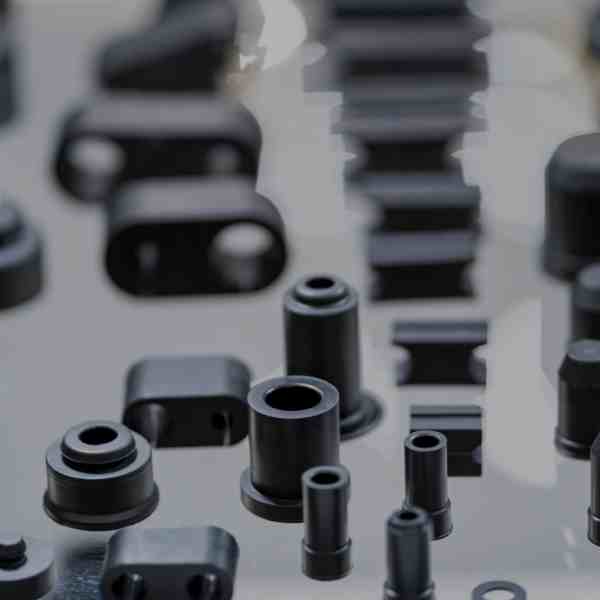

Plastic Injection Molding

Plastic Injection Molding to meet Low Volume Manufacturing Needs. Fast Turn-around

Injection Molding and Low Volume

Injection Molding is the process using designed cavities molds to make plastic parts in a short time. Low-volume manufacturing is the process of prototyping items and products in small quantities. Hybrid approaches that mix subtractive and additive manufacturing aspects help to lower total tooling, labor, and material costs while producing lower-volume items. When the product design is confirmed, only using one programming logic and the same manufacturing equipment, the low volume production can be completed.

The Advantages of Low Volume Manufacturing

It is growing in popularity since it allows manufacture and brand owner reduce the market investment excess risk. Many businesses have discovered that producing in small quantities enables them to come to market faster. On the other side, the first small production helps them test market, find out the popular tendency. They have room to modifiy their design and then put it to production manufacturing again. Plastic Injection molding is an ideal manufacturing way to gets same standard quality production parts for 1 machine and 1 way. It avoid a lot of manufacturing errors as long as the mold is designed and tested it well.

What Will DOMI Provide

DOMI Prototyping provides a series of manufacturing services to support your production needs.

Mold Tool Design: Upload CAD file to us. Our professional engineering team will give you feedback in a short time with mold tool design solutions about how to make your parts. DOMI have full CNC machine line for mold manufacturing.

Mold Trail: Before the low volume production, our team will have a test of the mold. Ensure the molded part have good surface looking. When you approve all the appearance feature, we will start the next step.

Production Injection Molding: Low volume requests just be finished in a short lead time. And all parts will be well packaged and delivered to your location.

3 Steps Low-Volume Production Solution

There is an easy way for you to get your low volume production with DOMI’s help.

- Contact us by email with your CAD file. We will choose the best manufacturing option for you.

- Confirm the manufacturing design proposal. Confirm what main process will be used, what post finishing will be made on the product. Lead time and shipment date.

- Waiting for the product’s arrival.

Why Choose Top Parts for Injection Molding

✓ Provides A Wide Selection Of Services In-House

DOMI provides a series of manufacturing services to support your production needs in the house. To meet your plastic and metal manufacturing needs. It is including CNC Machining, Plastic Injection Molding and Pressure Die Casting.

✓ Responsible Team

We have full experience engineers and machining specialists to support the whole manufacturing design and machining. We have good internal communication and control systems to make sure every step is smooth and easy.

✓ Top-Rated Screening and Verification Solutions for Materials

We see the quality as the key to success. We provide sophisticated incoming product screening and validation to guarantee that your raw materials meet your precise product standards.

✓ Preparation For Remote Control And Manufacturing Assistance Design

We have close in touch with our client for every machiing step. You can always know how your project runs and where the project schedule goes. We keep tight tolerance even in the production machining.

✓ Carefully Maintain Your Tools

Considering the small batch production will have the situation of return order, we will maintain your tools until your further requests. For the CNC machining, we will keep the features for the customer products. For the plastic injection, we will maintain the tool to avoid rust. For the die casting, we use the same way to save it.

Ready to Get Started?

DOMI Prototyping

DOMI has 30+ years of prototyping experience. We have seen the market change and have grown to meet the demands. We value experience and expertise, which is why the final product we deliver is precisely what our clients requested.