Finishing Services

A perfect product cannot do without the assistance of surface finishing.

DOMI has multiple options for you.

What Kind of Finishing Services Does DOMI Offer?

We offer many surface finishing to complete your project, whether metal or plastic, a single prototype or a large-scale run.

- Anodizing

- Painting

- Color Matching

- Printing Methods: Pad and Silk Screen

- Polishing and Sanding

- Brightening using Vapors

- Blasting

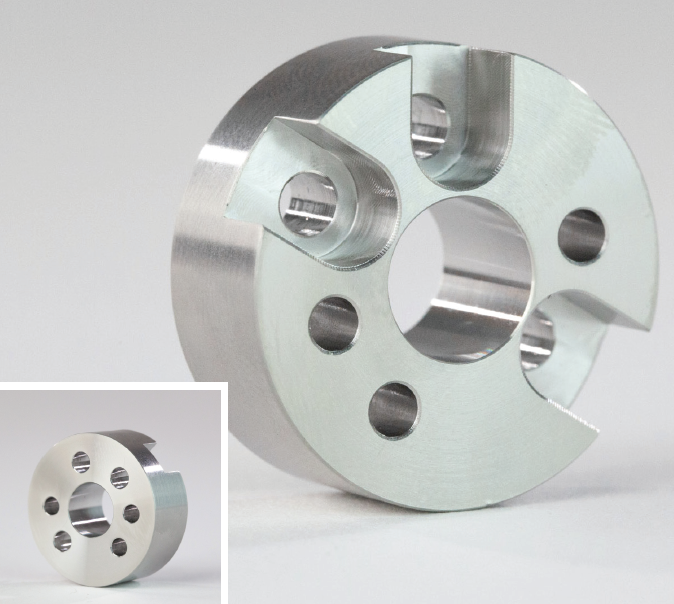

Anodizing

Anodizing aluminum, magnesium, or titanium is a specialty for DOMI Prototyping. The anti-corrosion, wear resistance, heat dissipation, and surface hardness benefits of anodizing are all well-documented. It’s a terrific-looking surface treatment that’s also perfect for painting and priming.

Type II anodizing is what we often employ, and it enables us to give your components a variety of finishes, including dyes and tints. For surfaces that need even more abrasion resistance, Type III is indeed available.

Painting

A high-quality paint scheme is among the finest methods for making your item stand out from the competition. We have a clean painting room for this process and experienced technicians work with your project closely.

Color Matching

When you provide us with a product manufacturing with color request, it’s better you talk about color with internal standards, such as Pantone, Munsell, Federal, etc. We use high-end color spectrophotometers to take accurate surface color, shadow, and reflection readings.

Sanding and Polishing

Some manufacturing methods, when the part comes out from the machine, it already has nice finishing, like CNC machining, plastic injection molding. But if you need the surface achieve some certain smooth or glossy, then you need sanding and polishing to support.

Vapor Polishing

Vapor polishing is used to make polycarbonate (PC) material transparent. This technique is good for getting a perfectly smooth surface in hard-to-reach places, and it may also be utilized to fix minor surface flaws.

Blasting

Textures like icing, pebbling, and more may be etched into a surface by blasting. This purpose is to deburr, clean, and chemically prepare components for subsequent surface treatments.

Ready to Get Started?

DOMI Prototyping

DOMI has 30+ years of prototyping experience. We have seen the market change and have grown to meet the demands. We value experience and expertise, which is why the final product we deliver is precisely what our clients requested.