3D Printing

Creative and Customized

Best solutions for master pattern and concept design realistic.

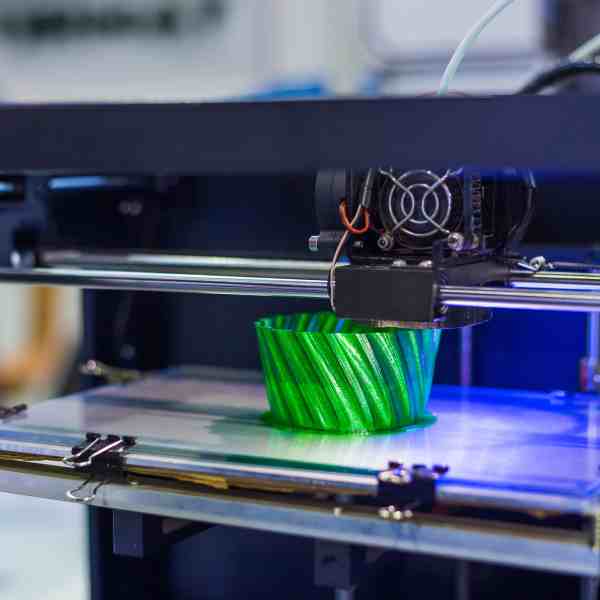

What is 3D Printing?

When people name 3D printing, it generally means plastic 3D printing. It’s an additive manufacturing that uses liquid plastic material and makes product layer by layer. 3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

DOMI 3D Printing Rooms

The Advantages of 3D Printing

Reduce Preparing Time

Unlike other machining processes, 3D printing do not need any support tools. It reduces the preparing time such as designing fixtures or adjusting the position in the machine. The liquid material is burned and built up the complex geometries in minutes.

Fast Turnaround

3D printing is a very fast manufacturing process. It’s ideal for the situation that customers need fast feedback at the very beginning of product development.

Flexible Manufacturing

For some complex shapes, CNC machining needs to use more than 2 machines to be achieved. However, 3D printing can be designed by the supports and build up the shape at one time.

Categories of 3D Printing

With the development of industry, 3d printing has become more and more popular. There are some common categories as follows:

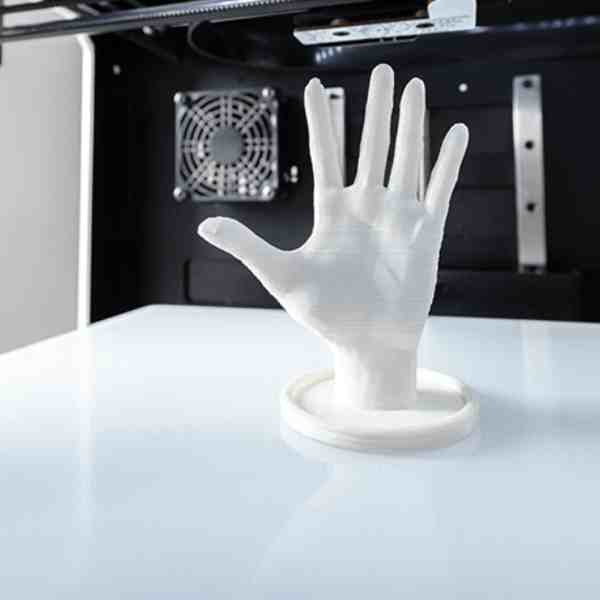

SLA 3D Printing: It’s a direct light processing (DLP), that uses light to project an image of the entire layer into the resin.

SLS 3D Printing:It uses a powdered raw material, typically a polymer. The powder sits in a container, where a blade distributes a thin layer of material onto the build area.

SLM 3D Printing: Well known as selective laser melting. It’s one of a few similar variations of SLS technology for metal 3D printing.

When You Need 3D Printing

Product Development

At the very beginning of product development, you have met a lot of guesswork, like how the product really looks like, how the practical function is used in certain conditions, awhether it looks like an attractive interface to win the market. 3D printing can solve all those doubts in a short time.

Support Vacuum Casting

Using 3D printing to be a master pattern is a smart way to save cost for the whole project. It helps to reduce the costs and keep all surface features on the pattern.

Material Options

PLA:

The most common 3D printing material is polylactic acid (PLA). It is a biodegradable plastic derived from renewable energy sources such as cornflour. Because of its low melting point, it is simple to utilize at home.

ABS:

ABS is ideally suited for elements that require strength and flexibility.

Metallic:

Use for pre-assembled components, final goods, and prototypes.

PC (Polycarbonate):

Polycarbonate, a less common form of plastic than the others, can only be utilized in 3D printers with nozzle designs and high temperatures.

Ready to Get 3D Printing Started?

DOMI Prototyping

DOMI has 30+ years of prototyping experience. We have seen the market change and have grown to meet the demands. We value experience and expertise, which is why the final product we deliver is precisely what our clients requested.